Manufactured sand is also known as artificial sand with particle size finer than 5mm, it is produced by rock exploitation, mechanical crushing and screening.

Material: Hard rock such as granite, diorite, basalt, conglomerate, sandstone, limestone, argillaceous limestone, dolomite, gneiss, quartzite, marble, slate, etc Soft rock such as tuff, nagelfluh, agrillaceous shale, argillaceous conglomerate, marl, mudstone, etc.

Application: It is suitable for applications in hydropower, highway, urban construction; the particle size can be combined and graded according to the different requirements of clients.

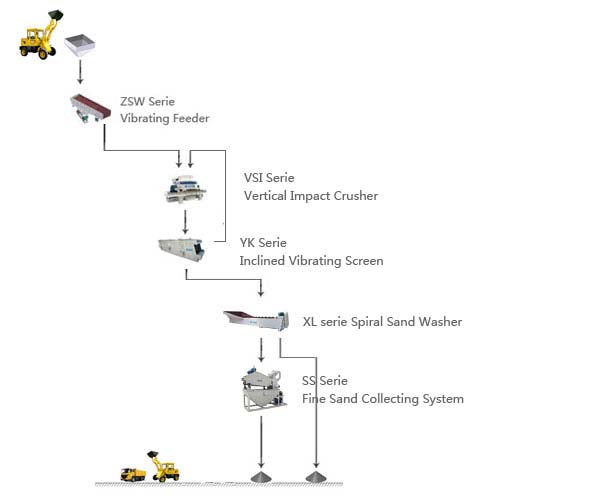

Equipments: Vibrating feeder, vertical shaft impact crusher, vibrating screen, sand washer, fine sand collecting system, etc.

In the process of Sanme wet sand making, new sand maker has replaced the rod mill with high running cost, which greatly improve the reliability of artificial sand production, and ensure the quality of product.

The process is specifically designed for the material less than 40mm(material will be primarily and secondarily crushed by jaw crusher, cone crusher, impact crusher, etc to the size less than 40mm), vertical shaft impact crusher is used in the configuration of production line, this crusher is the new type sand maker of Sanme, which has the features of high crushing efficiency(with the function of fine crushing and coarse grinding), simple structure, easy installation and maintenance, low operation cost and excellent particle size(cubic shape, low content of needle-like particles).

Aggregate with size of 0-40mm will be conveyed by electromagnetic feeder and belt conveyor to vertical shaft impact crusher for crushing, the crushed material will be conveyed to vibrating screen for screening, the material with size larger than 5mm will be conveyed back to impact crusher for crushing to achieve a closed circuit. The material with size less than 5mm will be conveyed to sand washer for cleaning, the cleaned material will be conveyed by belt conveyor to final product pile. In order to ensure the fineness module and sand grading, the sand washing water will be recycled by fine sand collection system to collect the fine sand with size less than 0.16mm.

1.The design of process is scientific and reaonable, which effectively ensure the quality and output of manufactured sand.

2.It is capable of crushing middle and high as well as extra high hardness material.

3.High automation minimize the cost of human resource.

4.Good sand grading, adjustable fineness module.

5.Low running noise level, less dust pollution.

Download the lastest products including Crusher, Mobile Crusher, Screens and Feeds of Sanme.

Jaw Crusher - Hydraulic Cone Crusher - Impact Crusher - Sand Making Machine - Hammer Crusher

Copyright ©2009 Shanghai Sanme Mining Machinery CO., Ltd All rights reserved.